Master Strut Servicing Tool

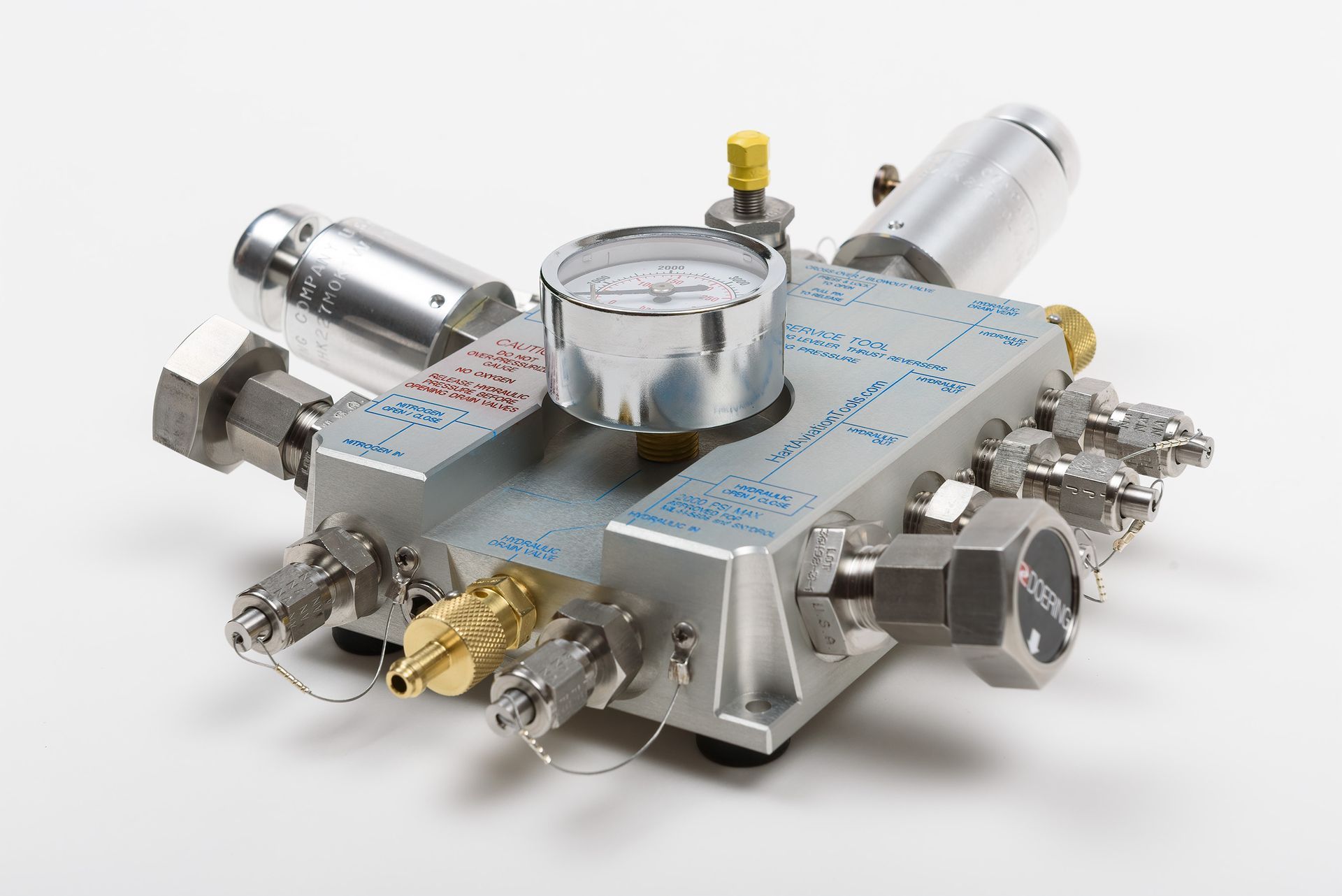

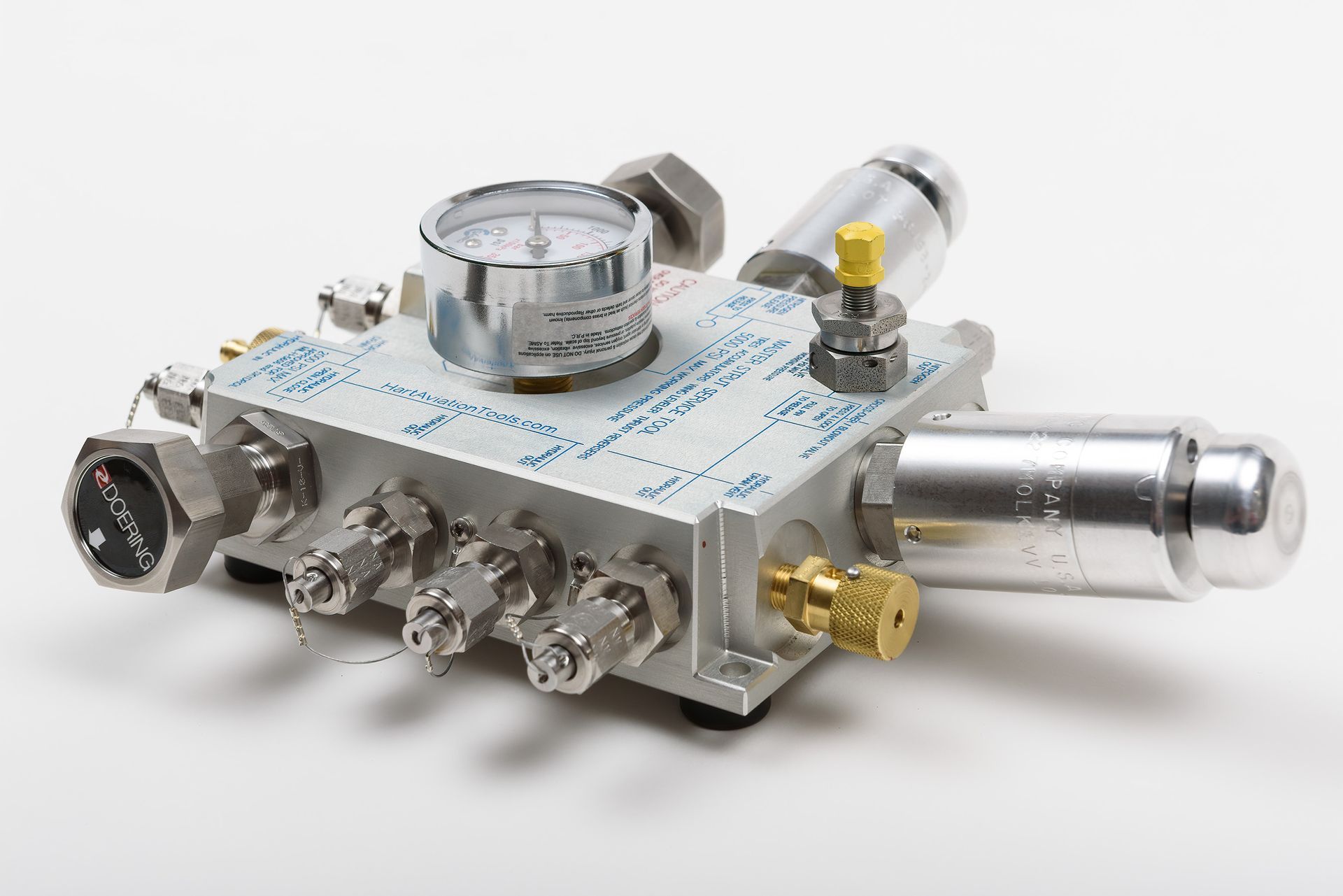

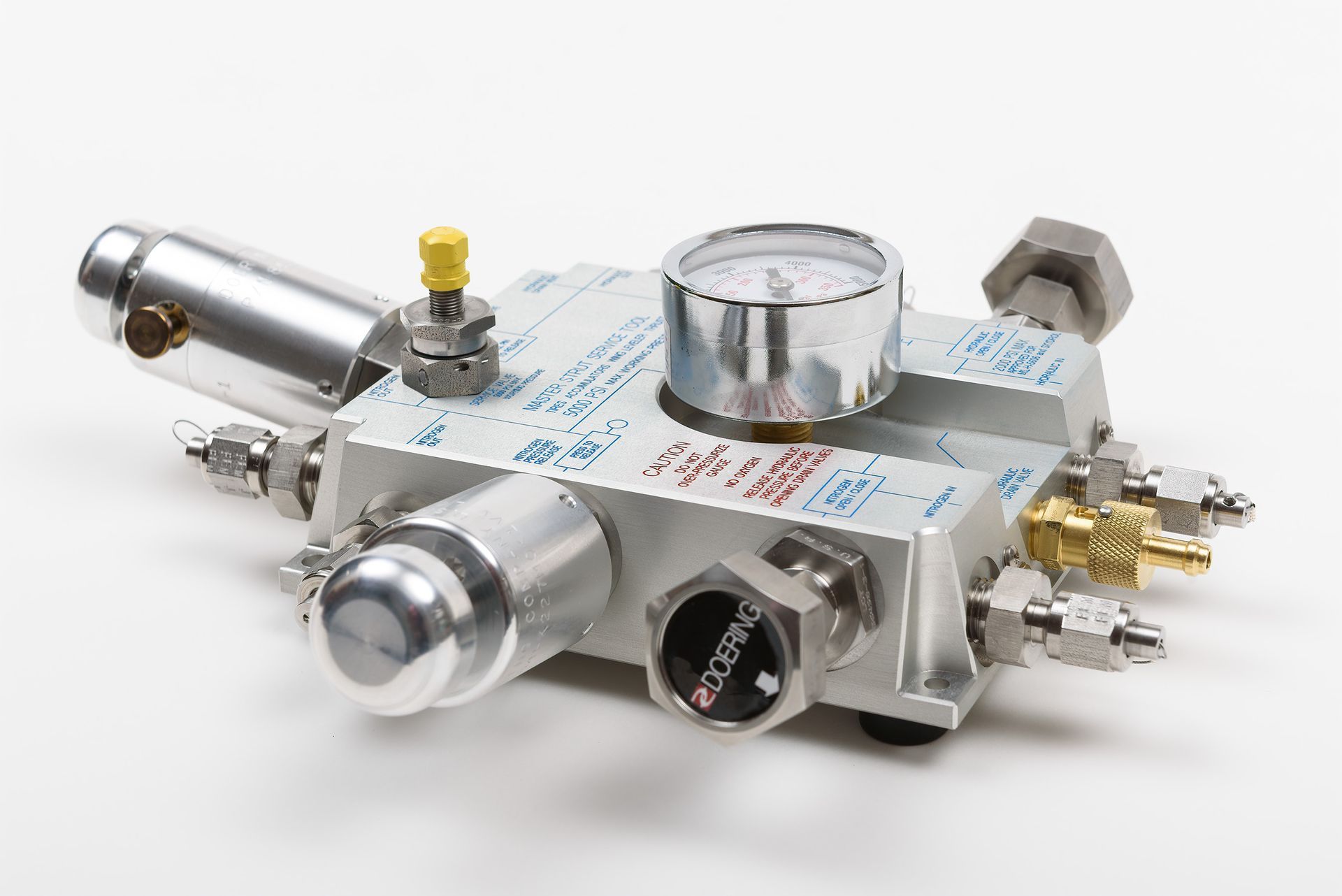

The main benefit of our Master Strut Servicing Tool is that you can hook up to both sides of the strut at the same time and service the strut through the parallel and independent nitrogen and hydraulic sides to the tool with no disconnecting or changing hoses until you're done. The hydraulic side is a two-way system. You can also drain your hoses safely, back through the tool, before you disconnect when you're done. No mess.

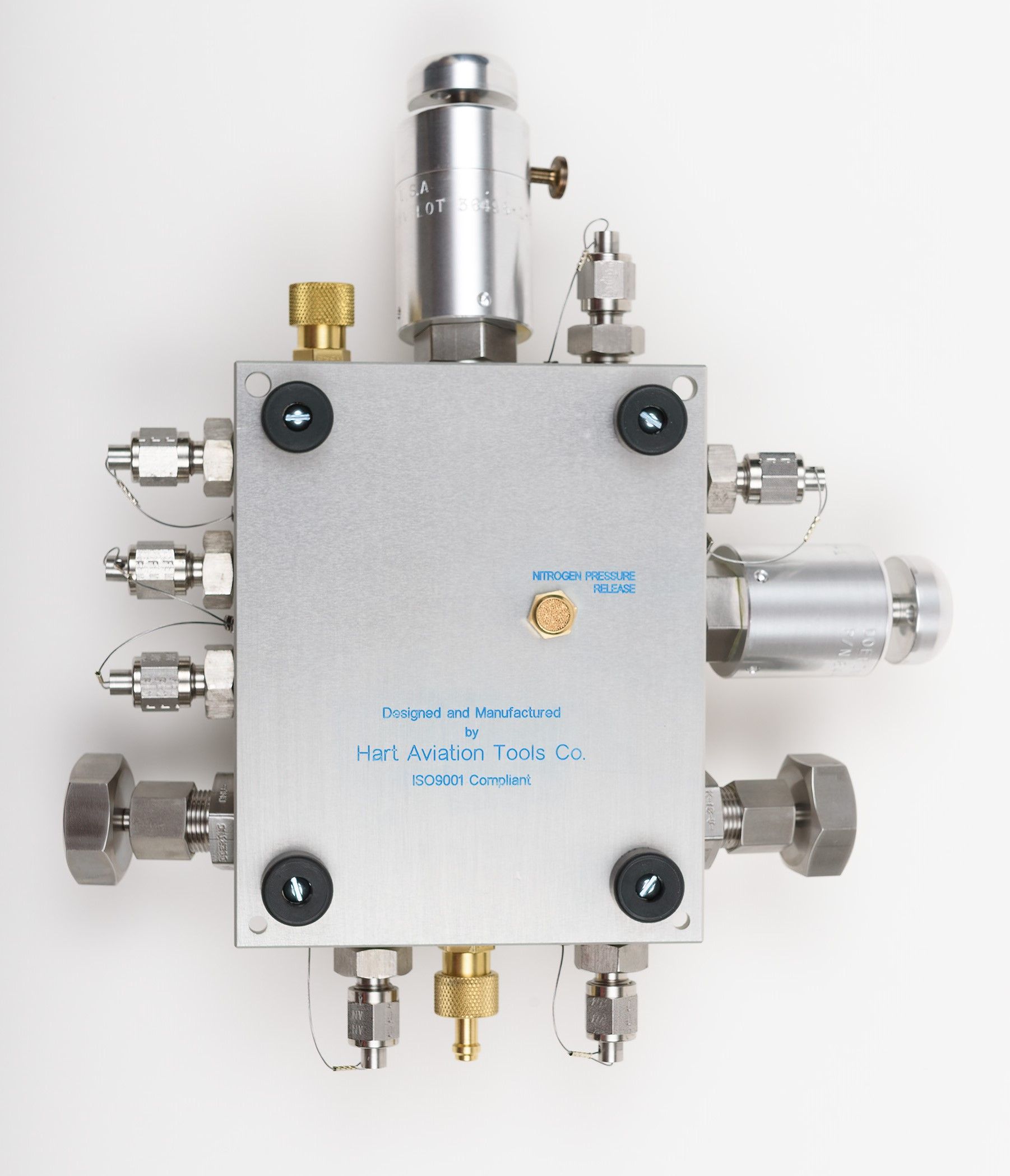

See the Top View of the tool to read and see the directions on how easily the tool is to operate. Now you can flush, service, charge, release pressure and drain hydraulic, all in one hook-up. Full control. One Action. Included are Cautions are silkscreened on the tool. "No Oxygen" and "Do not over pressurize the gauge". It comes with a 5000 psi gauge. Other size gauges are available.

Use the Cross-over/Blow-out Valve to clean out the tool, for clearing out the residual hydraulic fluid with nitrogen, when you're finished. This prevents old gooey drying MIL-5606 hydraulic fluid from clogging up the insides. Then install the AN-4 flared fitting caps, that are attached at the fittings, to prevent contamination. Patent Pending.

The tool has a Drain Valve for draining hydraulic fluid while flushing the strut by pumping the strut with a floor jack and draining the hydraulic hoses when you're done-before disconnecting the lines, and a Drain Vent Valve for aiding in draining the tool by eliminating internal vacuum lock.

It has a Pressure Release Valve that releases high line pressure nitrogen out the bottom of the tool through a muffler. This safely points away from the face and ears. This pressure release valve is not the typical tee handle valve that hurts your hand when operating it. The bottom has 4 rubber feet for scratch and shock-free operation.

The tool has 2 holes on the top corners to hang the tool on the landing gear for hands-free operation and easy draining. Or, to mount on a nitrogen cart or a stationary mount for bench work.

All the control valves are high quality cartridge valves rated to 5000 psi. The valve handles have locking features for holding the tool at any selected pressure. The tool is rated at 5000 psi on the nitrogen side and 60 psi on the hydraulic side. Hydraulic pressure can go as high as 2000 psi with both the drain valves in the closed position.

Manufactured with aircraft quality components and materials and is ISO 9001:2015 Certified Manufacture Compliant. FAA/PMA'd and TSO-C76, where applicable. RoHS compliant where applicable. The manifold is manufactured with 6061 aluminum and a Hard Anodized clear finish.

Request Quote

Complete the form below to receive a price quote for this product.